UNCOMPROMISING PREMIUM QUALITY

THE RIGHT BLADE FOR EVERY APPLICATION

Keen blades have been the hallmark of Solingen‘s industry for centuries and it is here we made our home in 1923. As a family firm, now managed by the fourth generation, we manufacture millions of blades every year. With over 130 fully-qualified staff, we are today one of the world‘s leading manufacturers of blades for technical and industrial applications.

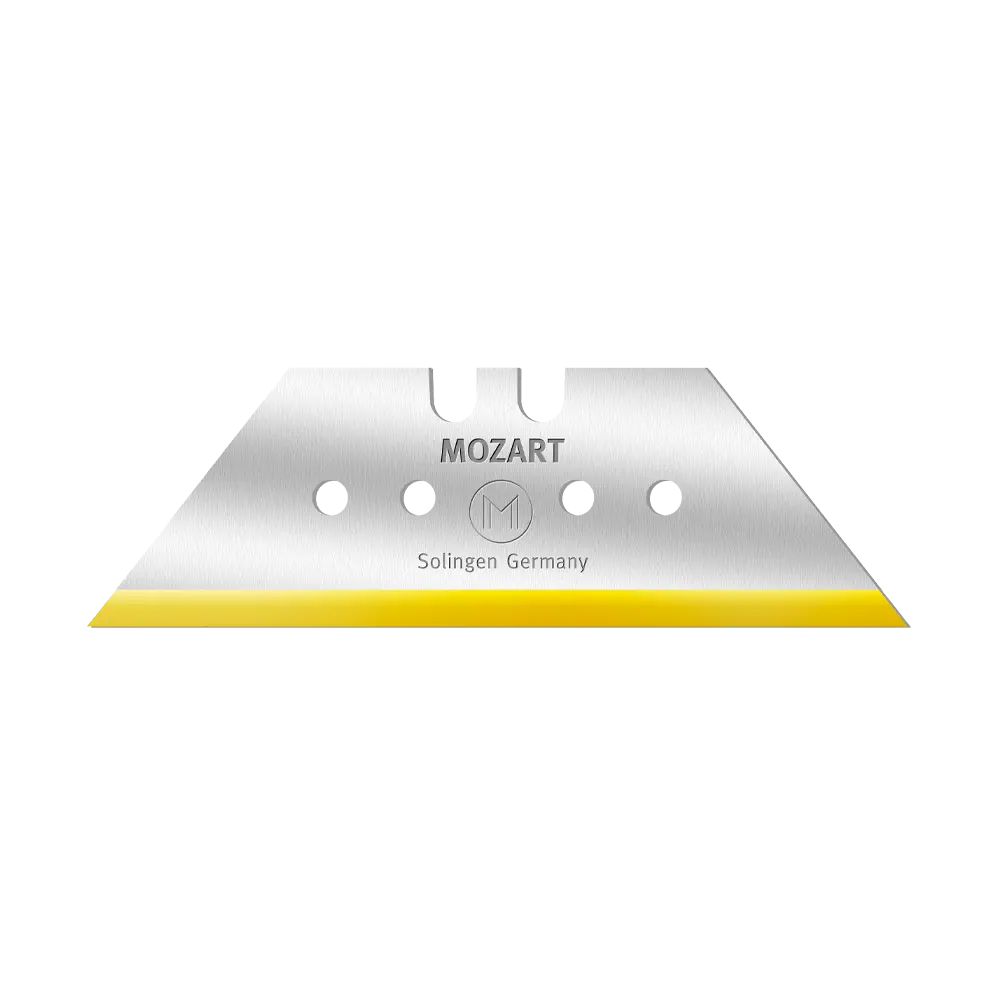

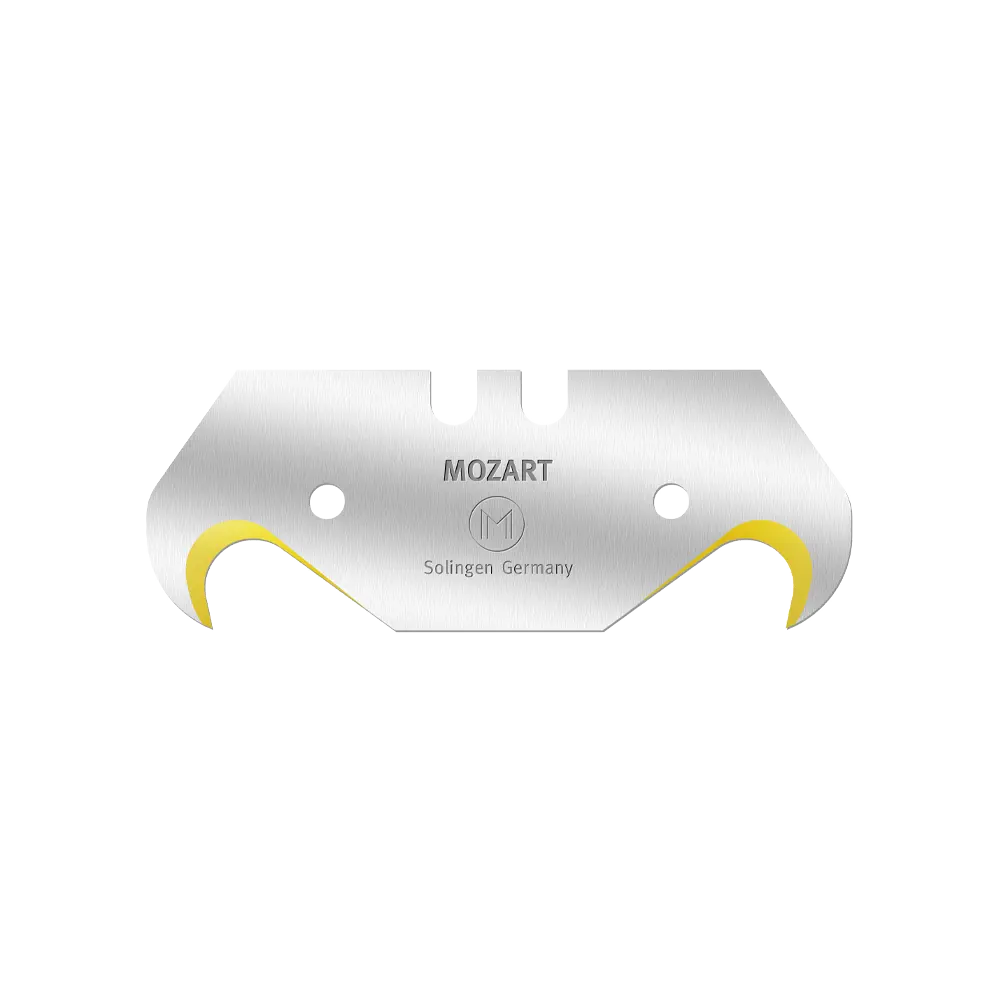

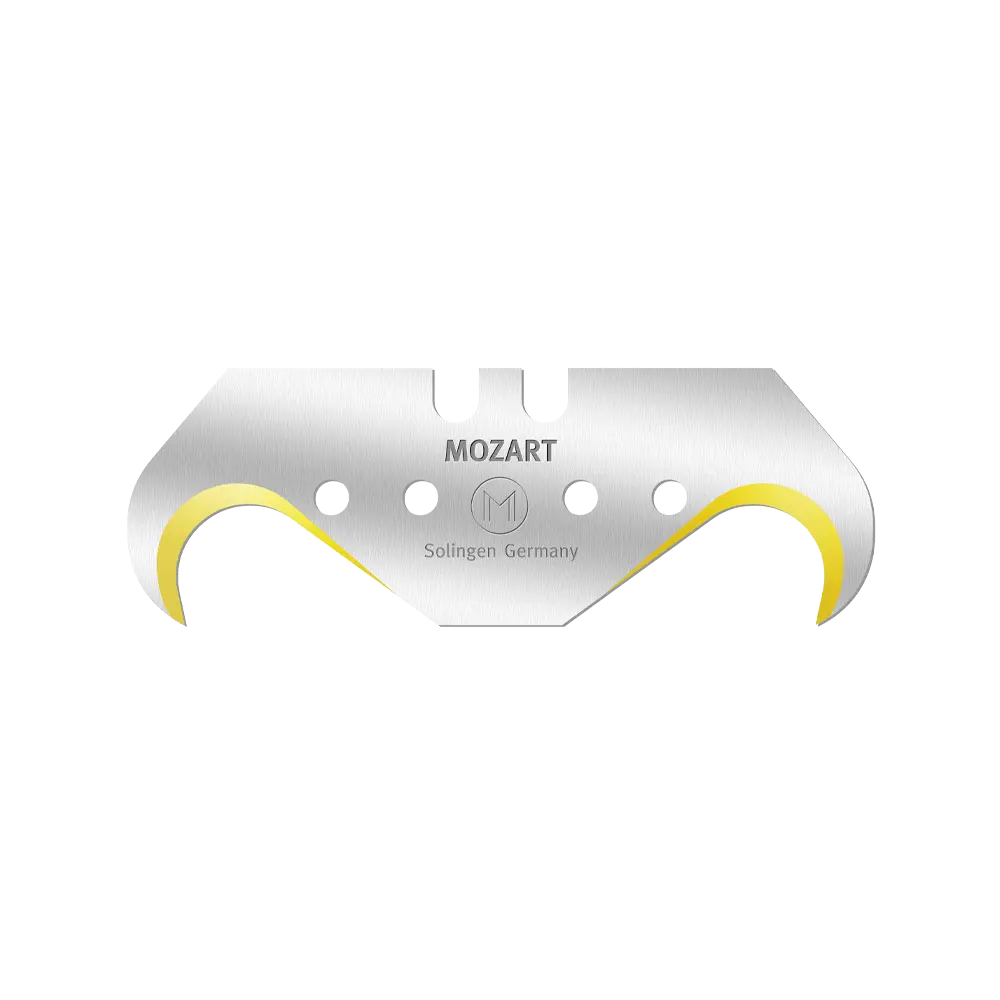

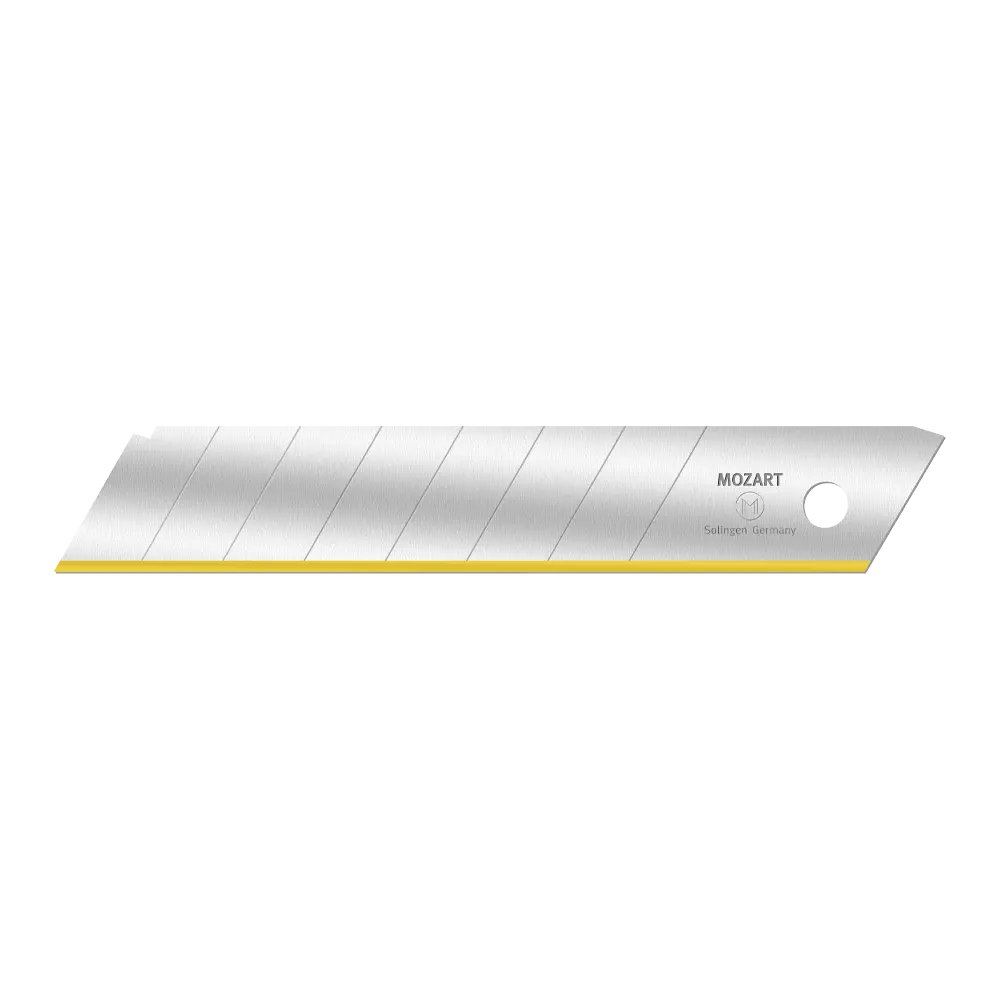

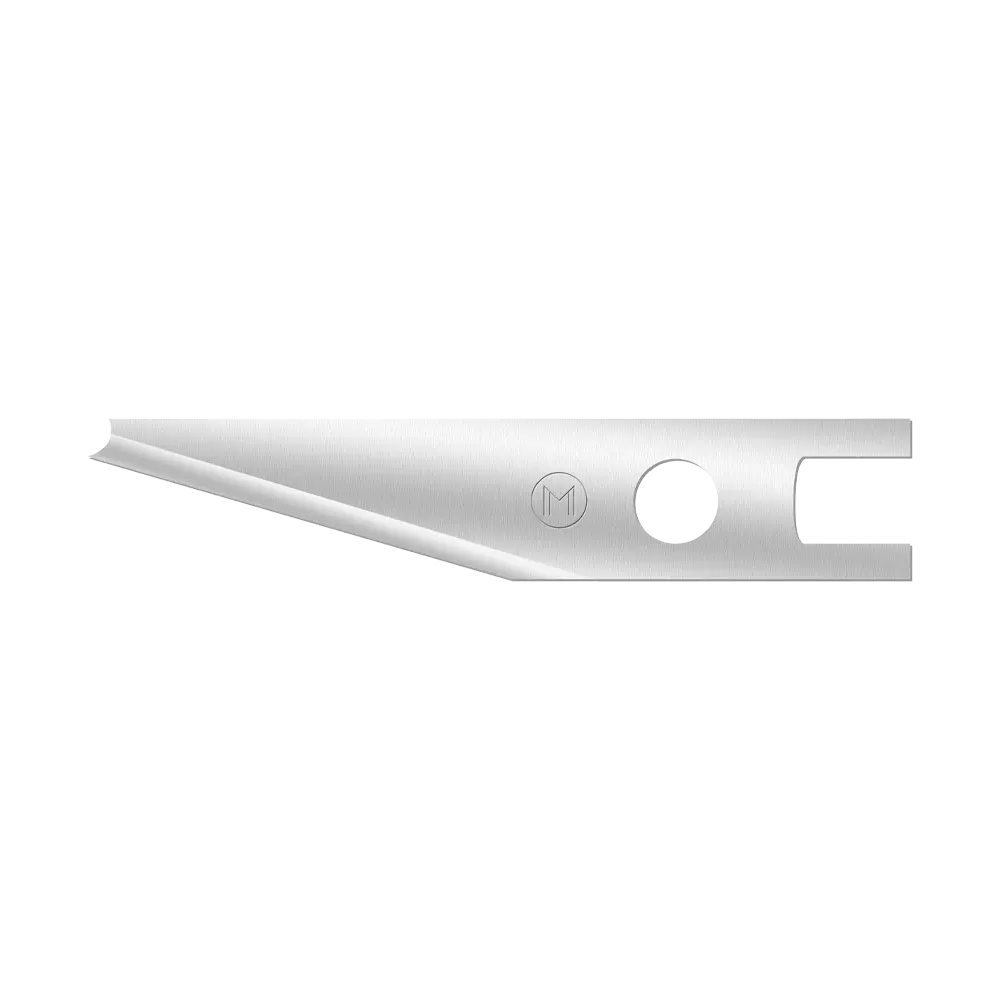

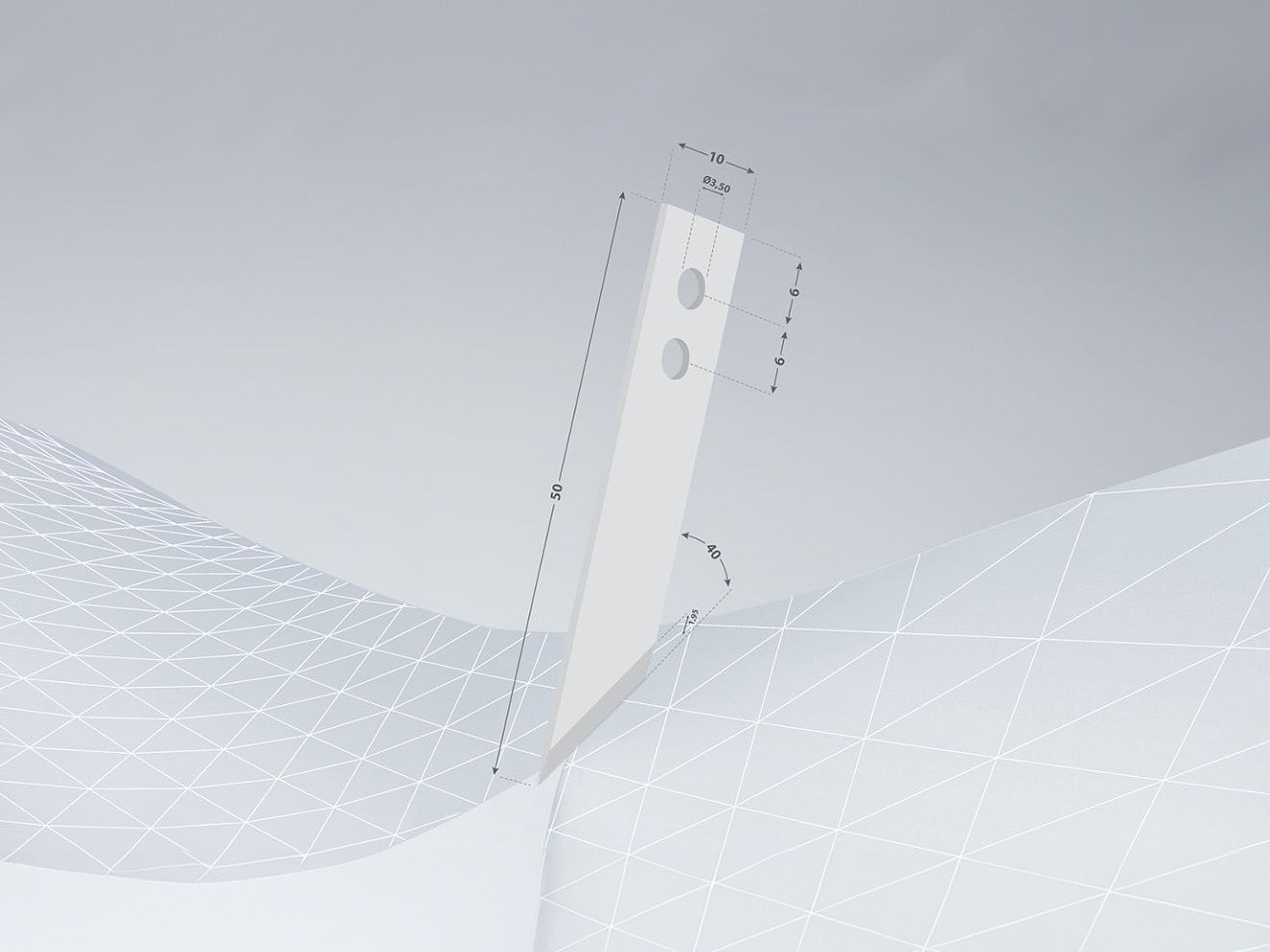

Utility Knives

MOZART ICE-HARDENING

FIRE AND ICE

After blanking, our strip steel is hardened to the required degree in a three stage process. The steel is heated in sensor-controlled straight-through furnaces in a hydrogen atmosphere. This is followed by the ice-hardening stage at –80°C, and this is followed by a brief annealing stage to remove stresses. This high-precision process enables us to achieve the ideal mix of hardness and toughness, and very close tolerances of +/- 1 HRC are standard in our production processes.

TIN Coated Blades

The most popular hard coating in the blade-making industry: provides high abrasive resistance and two to four-fold service lifetime extensions.

THE RECIPE FOR THE PERFECT BLADES

FROM HIGH-GRADE STEEL TO THE PERFECT BLADE

MOZART blades are manufactured in elaborate production processes and only leave the factory after strict quality controls. As one of the world's leading blade manufacturers, MOZART relies on Germany as a quality location. State-of-the-art technology and precise manufacturing guarantee the globally appreciated standard: "100% Made in Solingen". To maintain this standard MOZART uses a certified quality management system according to DIN EN ISO 9001.

PRECISION FOR EVERY APPLICATION