The right blade for every application

History

Sharp blades have been the trademark of the Klingenstadt Solingen for centuries, which has also been our home since 1923. As a family business in its fourth generation, we manufacture millions of blades every year to the satisfaction of our customers. With 100 qualified employees, we are today one of the world's leading manufacturers of technical blades. Our products are used wherever effective cutting applications are required. Trapezoidal and hook blades for professional floor layers, snap-off and scraper blades for painters, precision knives and blades for the plastics industry, specially manufactured blades for fiber and non-woven processing, blades for cutting foils and films and a wide range of special blades for customized special applications form the framework of our blade expertise.

Uncompromising Premium Quality

MOZART blades are manufactured in elaborate production processes and only leave the factory after strict quality controls. As one of the world's leading blade manufacturers, MOZART relies on Germany as a quality location. State-of-the-art technology and precise manufacturing guarantee the globally appreciated standard: "100% Made in Solingen". To maintain this standard MOZART uses a certified quality management system according to DIN EN ISO 9001.

Production Process

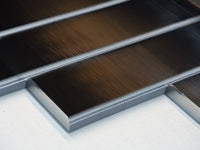

Strip Steel

Strip steel as a raw material undergoes incoming goods controls: surface, edge quality, straightness, metallurgy

Blanking

Blanking the outline conture, punching rated breakpoints and text markings

Hardening

- Process: Hardening – Quenching – Deep freezing – Tempering – Quenching

- Continuous process monitoring of hardness and warping

- Repeated inspections of molecular structure in metallurgy laboratory

- If necessary, additional surface treatments after hardening (lacquer, etching, polishing)

Grinding

- Strip grinding: straight grind along the upper edge.

- Hook grinding: plunge grinding for concave and convex shapes,

- 3-Hole grinding: Grinding of the upper and lower edges of the blades on conveyor belts

Snap-Off/Separating

The precise notching of the rated breakpoint is decisive for the snap-off process

Molecular structure and cutting analysis

- Continuous quality inspections at all production stages to prevent cumulative defects

- Analyses of the molecular structure and cutting behaviour guarantee our high quality demands

Packaging

Multistage packaging for optimum preservation and safty during transportation